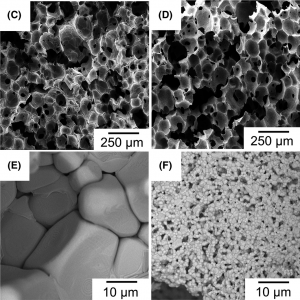

Porous barium titanate has gained significant attention in recent years for their potential use in applications such as scaffolds for bone tissue engineering, stress sensors, gas sensors, and many others. However, there is very little control over the grain size of the material during the sintering processes specially to achieve little or no growth of the starting powders. Here, using the two-step sintering method barium titanate foams were shown to be synthesized with controlled grain size of the struts without significant differences in the pore structure of the materials. In order to evaluate the applicability of two-step sintering for a variety of processing methods, highly porous (>80% porosity) foams synthesized through the direct polyurethane foaming method were used to create conditions furthest from bulk where two-step sintering has shown success. Two-step sintering parameters were identified and the processing conditions were confirmed to not alter the mechanical properties of the samples due to expected residual stresses or thermal shock resulting from the rapid heating and cooling rates employed.