Ionics

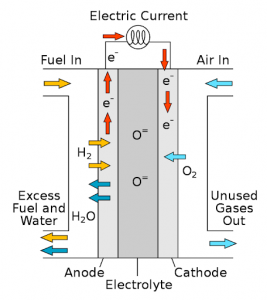

The United Nation’s Intergovernmental Panel on Climate Change concluded that green hydrogen plays an essential role in the transition to renewable energies. In large vehicles such as ships, trains, planes, and industrial vehicles, batteries lack a sufficient energy density to be practical, but hydrogen can be used as a fuel source to generate electricity in fuel cell vehicles (FCVs). Solid oxide fuel cells (SOFCs) are among the most developed technologies for converting hydrogen into electricity. They have received increased attention in recent years as an environmentally friendly power source. For SOFCs to be used in these applications, they need to operate in the intermediate temperature (IT) range of 400 – 800°C. However, current SOFCs do not provide sufficient power at these intermediate temperatures and must operate at or above 1000°C, a temperature far too high for use in FCVs. A key component of an efficient IT-SOFC is a solid oxide electrolyte with a high ionic conductivity at intermediate temperatures. We are continually investigating the properties of rare earth doped ceria high-entropy oxides, the most promising material for use in IT-SOFC electrolytes.

For more details of our work in this area, please check out our publications:

Solvent‐deficient method lowers grain‐boundary resistivity of doped ceria

Effect of a DC bias on the conductivity of gadolinia doped ceria thin films

Ferroelectrics: Effective Colossal Permittivity

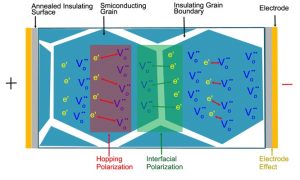

Barium titanate (BaTiO3, BT) is a material well-known for its excellent dielectric (ε’~3500) and piezoelectric properties, which allows for its utilization in a variety of electronic applications such as capacitors. The high relative permittivity and low dielectric loss of the material are favored in the microelectronics industry since it enables device miniaturization. Abnormally high relative permittivity (ε’~104–105), which is also referred to as colossal permittivity, can be induced in the synthesized nano-crystalline (250 nm) BT ceramic using starting nano-crystalline BT powder and spark plasma sintering (SPS) technique. SPS is a fast sintering technique that allows for the densification of ceramics while maintaining small grain size. This made possible by the short sintering time and relatively low sintering temperatures employed.

Our work deals with inducing colossal permittivity by using SPS technique and nano-crystalline BT starting powder. Dielectric spectroscopy analysis was performed on SPS BT ceramics in order to better understand and investigate the polarization mechanisms associated with the colossal permittivity of BT ceramic. In addition to interfacial polarization mechanism, which has been widely accepted for the origin of colossal permittivity in BT ceramics, we show that a hopping polaron mechanism co-exists as an additional polarization mechanism contributing to the colossal permittivity of BT ceramics. As a result, relative contributions of each polarization to the colossal permittivity were calculated: 65% hopping polarization, 20% interfacial polarization, and 15% electrode effect.

For more details of our work in this area, please check out our publications:

Suppressed grain growth in highly porous barium titanate foams by two‐step sintering

Conductive Glass Ceramics

Science is searching for ways to diminish vehicles’ contribution to the carbon footprint, and renewable energy sources are a promising alternative. However, according to the Department of Energy, electric vehicles need to increase their range to meet the performance of gasoline vehicles. Longer driving ranges require batteries with increased energy density. Lithium-air batteries weigh less than the popular lithium-ion batteries, allowing for an energy density five times higher than their industry-dominating lithium-ion peers. But before lithium-air batteries can have real-world application, the electrolytes responsible for ion transfer between the anode and cathode need improved efficiency and chemical stability.

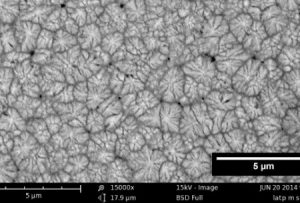

LiO2-Al2O3-TiO2-P2O5 glass ceramics are a encouraging candidate for the electrolyte in lithium air batteries. The Nasicon (sodium super ionic conductor) structure of these glass ceramics leads to excellent room temperature ionic conductivity. Additionally, microwave heating allows for a novel method to induce crystallization, leading to improved properties in this system. We are currently focusing our research on quantifying the kinetics of dendritic growth of the crystalline phase from the amorphous bulk. In the future, our work will include investigating the interfacial stability of LATP with lithium metal.

For more details of our work in this area, please check out our publications:

Kinetic Analysis of Crystallization in Li1.3Al0.3Ti1.7(PO4)3 Glass Ceramics

Microwave Processing for Improved Ionic Conductivity in Li2O–Al2O3–TiO2–P2O5 Glass‐Ceramics

Dielectrics: Barium Strontium Titanate Glass Ceramics

With environmental concerns that come from burning petroleum-based fuels in mind, the Department of Transportation and the Department of Energy are leading efforts to transition the United States to vehicles that use alternative fuel sources. Such vehicles include hybrids, plug-in hybrids, fuel cell electrics and pure electric vehicles which rely on power electronics to convert energy from the battery to the motor. In order to make electric vehicles a strong competitor against traditional combustion engine vehicles, the cost and efficiency of the power electronics and electronic machines must be improved. By finding materials with higher energy and power density, DC bus capacitors in the power inverter can have reduced size, improved efficiency and lower operating temperature.

We are investigating barium sodium niobate (BNN) glass ceramics to reach these goals . BNN glass ceramics are composite materials with the potential to be used in high pulsed power applications, which require materials with high energy density. They are part of a class of materials that combine a high permittivity crystalline phase with an amorphous phase that exhibits high breakdown strength. These combined properties lead to composite systems with high energy density. We are currently focusing our research on finding a relationship between the glass ceramic interface and energy storage properties.

For more details of our work in this area, please check out our publications:

Colossal permittivity and low losses in Ba1–xSrxTiO3–δ reduced nanoceramics

Piezoelectrics

Piezoelectrics are ubiquitous in everyday life and can be found in many everyday items like inkjet printers, diesel engines, X-ray shutters, MRI scanners, cell phones, microwave ovens, fire alarms, key fobs, and more. The piezoelectric effect allows certain solid materials to experience mechanical strain when exposed to an electric field and, similarly, create an electric field after being mechanically strained. For example, piezoelectrics are at work when music speakers create vibrations upon electrical stimulation.

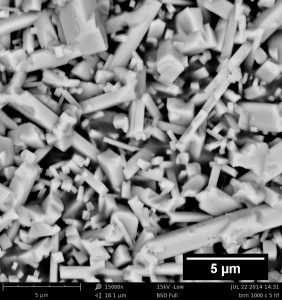

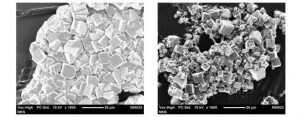

There is currently a great need for the development of piezoelectric materials that are not lead based. One such group of material is the Na1-xKxNbO3 (NKN) system. Our current research on this material is focused on growth of the crystal in the <111> orientation. By carefully controlling the temperature and pressure conditions on crystal growth, we hope to achieve this orientation through solvothermal and microwave-assisted synthesis. Recent experiments focused on measuring the dielectric permittivity of a slurry of pure NKN crystals grown through the solvothermal method.

The conventional approach to solvothermal synthesis is when a chemical solution is exposed to the environment within an autoclave. Instead, our approach has been to seal the chemical solutions in fluoro-polymer pouches. This approach minimizes the transient growth conditions caused by particle settling and allows multiple experiments to run simultaneously. Both endpoints and fractional compositions of the system have been successfully synthesized through this method. X-ray diffraction shows this method is successful in eliminating carbonate impurities that are common in NKN growth as a result of reaction with the atmosphere. Additionally, the effect of reaction time on particle size has been documented with the NKN system.

Our current research is focused on measuring the dielectric permittivity of a slurry of NKN to better understand the dielectric behavior and near-field particle interactions of the crystal before heat treatments. Measurements across a range of compositions and loading volume are ongoing. In addition to dielectric measurements of pure NKN crystals, we have plans to elucidate the oft under-reported thermal properties of this material. Thermal diffusivity, DSC and TGA measurements will be in future investigations.

For more details of our work in this area, please check out our publications:

Hydrothermal crystal growth, piezoelectricity, and triboluminescence of KNaNbOF5

Dielectrics: Dielectric Properties of Bi-Pyrochlores

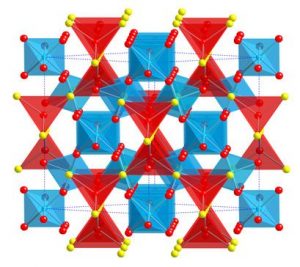

As the energy demands of the world increase, improved electrical components need to match the pace of technological improvements. Dielectric materials with high-efficiency, high-capacity energy storage will allow for smaller, more efficient capacitors. Materials with the pyrochlore crystal (A2B2O7) have recently become attractive dielectrics.

Capacitors are used in nearly every electrical device. They are composed of two conductive plates separated by a dielectric material that stores charge. Capacitors passively store and dissipate electrical charge, allowing for the steady flow of an alternating current and eliminating a direct current. Developing dielectric materials with high-efficiency, high-capacity energy storage will create smaller, more efficient capacitors.

Bismuth-based pyrochlores have been extensively studied due to their attractive composition-dependent dielectric properties. A combination of high permittivity values (usually above 100), low dielectric loss, and low sintering temperatures (1000°C ± 150) makes them good materials for dielectric components for embedded capacitors and multilayer ceramic capacitors (MLCC).

Bismuth-based pyrochlores have been extensively studied due to their attractive composition-dependent dielectric properties. A combination of high permittivity values (usually above 100), low dielectric loss, and low sintering temperatures (1000°C ± 150) makes them good materials for dielectric components for embedded capacitors and multilayer ceramic capacitors (MLCC).

Over the last decades, extensive research has been done in order to explain a phenomenon that is common to several pyrochlores and all Bi-pyrochlores. In order to understand the origin and necessary conditions for dielectric relaxation, the dielectric properties of Bi2Ti2O7 have been comprehensively studied as a function of temperature and frequency in order to clarify the presence of relaxation in this material, and in turn, better understand the nature of the dielectric relaxation phenomenon observed in Bi-pyrochlores.

For more details of our work in this area, please check out our publications: